Director's Corner

9 August 2007

Barry Barish |

Siting the ILC: Reference design for the conventional facilities

Where will the ILC be built? This is one of the first questions people ask me whenever I give a presentation on our ambitions to build a new accelerator for particle physics. The answer, of course, is that we just don’t know! Although we are working towards a siting plan, the uncertainty where the ILC will be built is likely to continue through the engineering design phase. Nevertheless, by working on designs for a set of “sample sites,” we have made a lot of progress in understanding key issues involved in siting. This is especially true for the scope of the conventional facilities and the estimated costs.

In the absence of a specific ILC site, we solicited sample sites from Europe, Asia and the Americas, and their designs have been developed in parallel. The approach we took during the reference design phase was to use requirements provided by each of the ILC systems (main linac, damping ring, injectors, etc.) as those designs evolved. The designs are for the 31 kilometre-long, 500-GeV baseline machine, although the sites all have footprints enabling a 1-TeV upgrade. All present studies are for deep-tunnel sites that have varying geological features and topographical constraints. We also plan to make an evaluation of shallow siting (either through a shallow tunnel or the 'cut and cover' solution) during the engineering design phase.

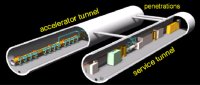

The main feature of the conventional facilities design is a double tunnel configuration, one containing the accelerator and the other serving as a service tunnel. For technical connections, there are three radiofrequency/cable penetrations for every rf unit, and for personnel access and safety, there are crossovers every 500 metres. The reference design consists of 72.5 kilometres of tunnels some 100-150 metres underground, 13 major shafts of at least 9 metres in diameter, 443 thousand cubic metres of underground excavation including caverns, alcoves, halls, and 92 surface “buildings,” covering 52.7 thousand square metres.

The requirements from accelerator systems were used to set the size of tunnels, shafts, underground caverns and surface buildings, as well as the related capabilities to accommodate installation, maintenance, personnel access and safety. We have made an initial attempt to minimise costs by reducing the number of major shafts to the thirteen needed to perform the parallel tunneling. A high priority systematic value engineering analysis will now be carried out during the imminent engineering design phase. We expect this to be an area where we can optimise the design and minimise projected costs before working with potential host countries on site-specific designs.

Our work on conventional facilities has been carried out by an international group who have worked particularly well together in the face of doing three separate regional designs. This effort was led by Jean-Luc Baldy (CERN), Atsushi Enomoto (KEK) and Vic Kuchler (Fermilab), and they will soon be holding a kick-off meeting at KEK with our new Project Management to plan the approach and goals for the conventional facilities effort during the engineering design.

I would like to end today's column by saying a few words about Jean-Luc, who will soon retire from CERN and his work for the GDE. We will miss his invaluable experience, his open-minded and insightful problem solving, and especially his collegial personality. I have enjoyed very much having him as part of our team. I would like to thank him and wish him all the best for the future!

-- Barry Barish