Director's Corner

11 October 2007

Barry Barish |

Unified versus plug compatible designs

We are now making the transition from completing the International Linear Collider reference design to beginning the engineering design phase by holding a set of kick-off meetings to cover the major areas of the machine. The ILC project managers have organised this intensive set of meetings in order to interact closely with task leaders and team members who will be responsible for carrying out the actual design tasks. The meetings are covering a broad spectrum of issues that need to be understood before drawing up detailed work packages that will define our work toward the Engineering Design Report. The kick-off meetings cover issues that vary from organisational ones and technical topics to subjects that will have important consequences in the design work. A very good example of the difficult questions currently under discussion is to what extent we will require unified designs versus plug compatible designs for the cryomodules.

Our goal for the engineering design is to produce mature documented designs, costs and plans for the ILC that can then be used as the basis of a proposal to our governments for a construction start. One very important question in coordinating our widely varied and dispersed programme is to what extent we want to seek a global unified design. In the extreme case, the unified designs will result in one set of drawings and costs. At the other extreme, the plug-compatible designs will be regionally optimised, but maintain a set of standard dimensions and parameters that allow them to be used interchangeably. Perhaps the final answer is somewhere inbetween.

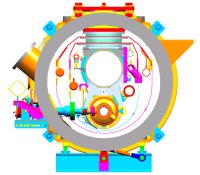

Constructing and assembling the 1500 required cryomodules for the ILC illustrates well the unified design vs. plug-compatible design dilemma. These cooled vessels that contain the superconducting radiofrequency (SCRF) cavities, tuners, couplers and other instrumentation, are at the centre of our design. Each 12-metre-long vessel will be powered by RF, and in tandem accelerate the electrons and positrons to a centre of mass energy of 500 GeV (billion electronvolts). No matter where the machine is sited, we plan to build these cryomodules in all three regions -- the Americas, Asia and Europe.

A view of the cryomodule kick-off meeting at KEK (photo: Nobu Toge, KEK) A view of the cryomodule kick-off meeting at KEK (photo: Nobu Toge, KEK) |

Akira Yamamoto, a GDE Project Manager, poses the question of unified versus plug compatible design (photo: Nobu Toge, KEK) Akira Yamamoto, a GDE Project Manager, poses the question of unified versus plug compatible design (photo: Nobu Toge, KEK) |

Design work on SCRF technology is ongoing in all three regions. Europe provides ten years of experience from R&D for the ILC-forerunner TESLA proposal, planned by the TESLA Technology Collaboration under DESY leadership. This design is now being employed in the XFEL project, a three-kilometre X-Ray free-electron laser that will be built at DESY. The XFEL project will provide us with very valuable 'real world' experience and information on building, testing and eventually using similar cryomodules for the ILC. In the US, efforts led by Fermilab to develop a fourth-generation cryomodule are underway, and this latest design will have some significant modifications from the XFEL cryomodule. In Japan, also starting from TESLA design, collaborators are developing ILC designs that included R&D on alternate cavity shapes. They are also developing cryomodule designs through industry.

The merging of the various regional cryomodule efforts presents a challenge. Divergence in designs at this early stage may lead to such problems as how to compare costs and how to insure global competition for components. On the other hand, requiring a unified design constrains the optimisation of technical components in each region.

An additional issue we cannot ignore is that we have yet to demonstrate that we can consistently achieve our design goal of 35 MV/m (megavolts per metre). Therefore, we must be prepared to make design changes to achieve our goal (or reduce the gradient). Tests are underway to demonstrate the design gradient by sometime in 2009, and these results must inform the final designs we incorporate in the EDR, which is scheduled for completion in 2010.

Our project managers are carefully weighing the arguments for issues like unified versus plug-compatible designs. There are many other considerations like these where their guidance will be crucial for carrying out a successful engineering design. This particular issue, like many others, is so complex that it will undoubtedly take some time to decide to what extent we will create a unified versus a plug compatible design. This question is not resolved at the present time, but stay tuned as the story unfolds.

-- Barry Barish