Director's Corner

26 November 2008

Progress on our Technical Design Phase goals

Today's issue features a Director's Corner from Marc Ross, Project Manager for the Global Design Effort.

Last week several hundred scientists and engineers gathered at the new Forum Event Center of the University of Illinois at Chicago for LCWS 08 and ILC 08. Once per year the Global Design Effort hosts a plenary meeting to which the entire community is invited to hear progress, plans and general presentations, and for 2008 this meeting was ILC08. The last such meeting was the very successful LCWS07 held in June 2007 at DESY. Although our venue was a rather brisk downtown Chicago in November, the meeting was warm and convivial and, I believe, as successful as LCWS07.

We opened the meeting with a reminder of the three main aims of the GDE during the Technical Design Phase (TDP). In order to achieve our goals we must: 1) ensure that the international ILC community continues to grow (especially through the development of collaborative activities); 2) produce the technical information required submit the project for approval, and 3) coordinate the world-wide R&D programme. I would like to pick out two items from the meeting as examples of our progress towards the above.

Superconducting RF Cavity Gradient

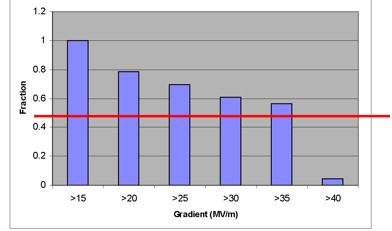

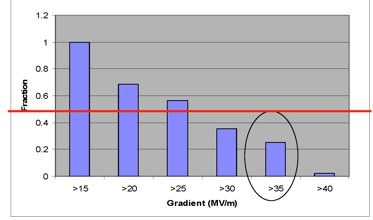

One of our most important and most visible research activities is focused on increasing high-gradient performance of nine-cell superconducting cavities and on estimating the production yield. Exciting new data that show real progress towards our ultimate TDP goal of 35 megavolts per metre (MV/m) with 90 percent yield were presented at ILC08. Our target for Technical Design Phase 1 - to be completed in 2010, is a yield of 50 percent. The top figure shows the combined yield of vertical-dewar nine-cell cavity tests from Jefferson Lab and DESY done in 2008. More than half of the cavities fabricated by one of our primary vendors passed the 35 MV/m limiting gradient threshold. The figure below it shows the observed yield when all cavities, 19 each coming from three vendors, are included. One of the challenges before us, for TDP-1, is to understand the vendor-to-vendor differences and work through these in order to achieve a more reliable, higher-statistics result. These data were first presented at the TESLA Technology Collaboration (TTC) meeting held in Delhi, India, in October and reflect the success of technical recommendations from the TTC.

Although these tests were carried out in only two of our three regions, Europe and America, the key diagnostic which will carry us closer to the goal of 90 percent yield was developed in Asia. This is the tool which allows microscope-quality inspection of the internal cavity surface, and extensive results were presented at ILC08. The results demonstrate its effectiveness, especially for cavities that are quench-limited at gradients below 20 MV/m. More than 20 cavities have been fully mapped with the inspection system, and the correlation between features observed in the mapping and the actual quench-causing defect is excellent for this sample. The system promises early identification of cavities with a low gradient limit, perhaps before surface treatment and cryogenic tests are completed. We hope to demonstrate this modified quality control process in 2009. I am quite pleased with the manner in which the three regions' activities have complemented each others' strengths in this critical R&D and brought us closer to our stated TDP-1 goal, albeit with only a small statistical sample.

XFEL Technical Coordinator Thomas Hott and Lars Hagge, leader of the XFEL work package 'Information & Process Support'. XFEL Technical Coordinator Thomas Hott and Lars Hagge, leader of the XFEL work package 'Information & Process Support'. |

Collaboration with the European XFEL Project - Conventional Facilities

The two primary cost-drivers in the Reference Design Report are the main linac and the conventional facilities. Together, these account for 79 percent of the RDR value estimate. We are very fortunate that, through DESY and the ongoing European XFEL (X-ray free-electron laser) project activities centred there, we can actively participate in and help with a real project which uses ILC-like technology and infrastructure. The XFEL project schedule is also ideal; it is now fully underway and should be nearing completion at the end of the TDP. At the meeting last week, the ILC Conventional Facilities/Siting (CFS) Working Group, led by Vic Kuchler (Fermilab), John Osborne (CERN) and Atsushi Enomoto (KEK), put the finishing touches on plans to meet with the XFEL CFS and Technical Coordination teams to discuss in detail their designs and near-term XFEL project activities. We will meet next week at DESY and hope to continue face-to-face meetings to develop stronger ties during 2009. This offers us a unique opportunity to sharpen our design activities and, at the same time, to help busy XFEL engineers and managers. The XFEL Project Technical Director, Reinhard Brinkmann (DESY), has consistently and strongly encouraged this interaction between the two project teams. I have high expectations that this relationship will grow to be quite strong and interactive and that it will provide the strength and real-world experience the project should have as we move forward to submission for approval at the end of TDP in 2012.

-- Marc Ross