Director's Corner

29 January 2009

ILC power

Today's issue features a Director's Corner by Ewan Paterson, Member of the GDE Executive Committee.

I have many times been in the situation where I took an interested non-expert on a tour of SLAC National Accelerator Laboratory and explained how it relates to a future project, the International Linear Collider. I would often say that in several ways it is similar but ten times longer. This particularly gets a lot of attention while standing in the 3-kilometre-long klystron gallery where one is never sure that you can really see the end! This immediately leads to the question "where could you build something that is 30 kilometres long?" The fact that it would be mostly in underground tunnels and could be built almost anywhere in the world is usually a satisfactory answer.

Still standing in the SLAC klystron gallery and listening to the 'hum' of the modulators and klystrons, the next question is usually more difficult and requires a longer answer. "How much power will the ILC use?" The simple answer is: between 200 and 250 megawatts (MW) when all systems are operating for the research programme and approximately 50 MW during the scheduled downtimes which occur over two to four months of the year. These numbers are typical for existing high-energy accelerator laboratories like Fermi National Accelerator Laboratory (Fermilab) in the US and CERN in Europe. I could add that if we took the original SLAC linac technologies and scaled them to the ILC energy and luminosity, then the power consumption would be between two to three times larger. We continue seeking ways to reduce the capital and operating costs of the design while maintaining the same physics capabilities.

One design option which is presently being explored is to halve the number of bunches in the pulse train while retaining the same charge per bunch. This gives half the beam power and the luminosity is maintained using stronger focusing and a smaller beam spot in the interaction region. This reduces the input power to the linac and the heat load, and therefore reduces cooling requirements in many other systems. However, the impact on the beam delivery system and physics detectors is too complex for this column but many details of the ongoing studies can be found here.

These studies, using old and new ideas in optical design, will continue and expand over a range of parameters including high energies to understand the tradeoffs and sensitivities of an interaction region that has new tunability. In my opinion, even without the low power option described above, the addition of some new capability will give more freedom in optimising the ILC for different physics scenarios. The presentation (again link from above) includes a simulation of colliding beams which clearly shows why we physicists use the term 'disruption' in discussing the beam-beam interaction of colliding beams in linear colliders.

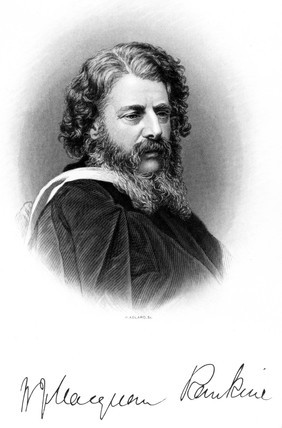

Rankine (Scots Physicist, 1820-72) was an early leader in the science of thermodynamics where much of the motivation was energy efficiency and the target technology was the steam engine. Rankine (Scots Physicist, 1820-72) was an early leader in the science of thermodynamics where much of the motivation was energy efficiency and the target technology was the steam engine. |

It should be noted that for the design parameters in the Reference Design Report at 500 GeV in the centre of mass, each beam carries of the order of five percent of the ILC total accelerator systems power, which is roughly 215 MW. Nearly all of this power ends up cooling systems in what is referred to as 'low-grade (temperature) waste heat'. This heat is being carried in water-cooling systems at locations spread over large distances and has to be disposed of. This is a common problem in many industries around the world, and there is increasing research into ideas on how to use this waste heat in some beneficial manner rather than just getting rid of it.

Amongst these ideas is using the hot water directly in heating systems or in chemical processing systems such as the production of bio-fuels from organic waste. There are obvious scheduling problems with these approaches and turning this heat back into mechanical work or electricity would be more flexible and attractive. There are many research programmes around the world using different technologies directed towards cost-effective use of this heat to generate electricity.

Today we have commercially available organic Rankine cycle generators from several parts of the world. The Rankine cycle refers to the closed-loop thermodynamic cycle that is used in gas, coal or nuclear power plants in transforming heat energy to mechanical and electrical energy. The term organic refers to the use of working fluids such as modern refrigerants that are environmentally friendly and can operate at lower temperatures than water. They use waste industrial or geothermal heat as input and produce electricity with 10 to 20 percent energy efficiency. They also use much of the technology of modern large-scale refrigeration equipment to reduce cost. However, to achieve these efficiencies at reasonable cost, they still need input temperatures that are somewhat higher than those we need to cool our equipment to maintain reliable operation.

Unlike the low beam power option, these and other ideas would, today, increase capital cost while reducing power consumption. However, perhaps in the long-term future this will change! With the global efforts in improving energy technologies, they may become part of the studies of various ILC upgrade programmes.

-- Ewan Paterson