Director's Corner

19 November 2009

Barry Barish |

The Spallation Neutron Source at Oak Ridge

In planning for a new large initiative like the International Linear Collider, it is important to learn as much as possible from existing projects that have relevance. In that spirit, we have invited presentations from other projects at our large workshops. At the American Linear Collider Physics Group workshop at Albuquerque (ALCPG09), we had a very informative presentation by Stuart Henderson of Oak Ridge on "The Spallation Neutron Source (SNS) Linac: Performance and Operational Experience." The SNS is the most powerful proton linac in the world and uses similar technologies to those proposed for the ILC.

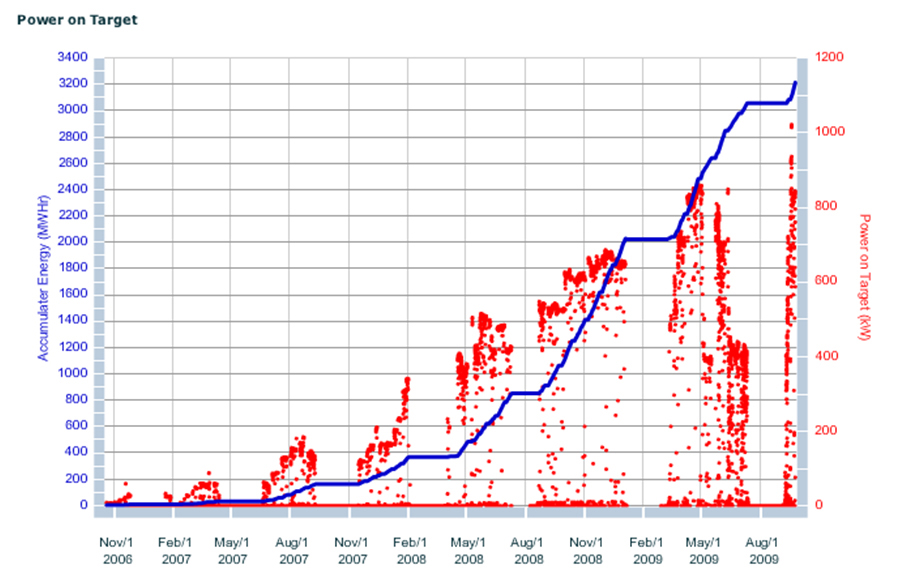

SNS is an intense–pulsed neutron source built by a partnership of six US Department of Energy laboratories for research and industrial development. It was completed in 2006 at a cost of 1.6 billion dollars and has been going through three years of commissioning and ramping up the performance. During that period the beam power has been increased from around 5 kilowatts to (very recently) 1 megawatts, availability from around 60 percent to 85 percent and the beam energy from 840 MeV to 930 MeV.

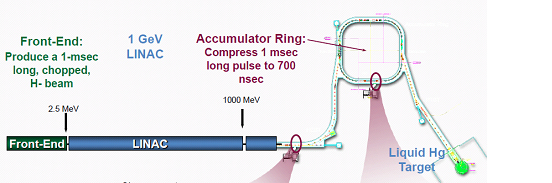

The SNS accelerator consists of an ion source that produces a millisecond–long chopped H– beam that is accelerated to energy of 2.5 MeV. The ion source is followed by a linear accelerator that accelerates to 1 GeV. The linear accelerator (linac) is made up of three different types of accelerators best matched to the energy of the accelerating particles. The first two are normal or room–temperature copper cavity configurations and the long final section contains ILC–like superconducting niobium cavities cooled with liquid helium to an operating temperature of 2 K. The emerging H– ions from the linac are then brought into an accumulator ring through a stripper foil that strips the electrons from the negatively charged hydrogen ions to produce the protons (H+) that circulate in the ring. Approximately 1200 turns are accumulated, and then all these protons are kicked out at once, producing a short intense pulse. These protons strike a mercury target that produces neutrons through the spallation nuclear reaction process. At full power, SNS will deliver 1.4 megawatts of beam power onto the target.

Liquid mercury was chosen as the target material for the intense proton beam, because of the enormous amount of energy that the short, powerful pulses of the incoming 1–GeV proton beam deposits in the spallation target. Mercury is not damaged by radiation, it is liquid at room temperature, it is better able than a solid target to dissipate the large, rapid rise in temperature and it can withstand the shock effects arising from the rapid high-energy pulses.

The science programme at SNS centres on studies that employ devices like neutron spectrometers to determine the positions, or arrangements, of atoms in crystals, ceramics, superconductors, and proteins. Instruments to measure inelastic scattering also require measurements of the time of flight of the neutron. This rich science programme is only beginning at SNS and with future improvements in both detector instrumentation and the high power pulsed neutron beam will lead to a long, active future.

Stuart Henderson commented during his presentation at ALCPG09 on what has been learned from the SNS experience that is applicable to the ILC, especially regarding the operation of the superconducting pulsed linac. A lot of detailed experience has been gained regarding accelerator physics issues like heating by electron loading, multipacting, coupler issues, turner issues, beam loss, monitoring, etc. At this point, operating parameters provide stable and reliable operation. Importantly, they have observed no cavity performance degradation to date and cryomodules have been successfully repaired without disassembly. He stressed the importance of an aggressive maintenance strategy to fix problems before they limit performance.

Even more directly, Stuart said that many features of their design originate from the Tesla technology also used for the ILC, including couplers, tuner assembly, fast piezo–electric control and even aspects of cavity processing incorporated into procedures. He said that in many ways the SNS superconducting linac is an ILC linac "en–miniature" and it provides a real–world example of operational limitations that the community is wise to learn about.

We were very pleased to have Stuart Henderson's talk and we thank him and wish him and his colleagues much success in the machine operations and science program at SNS. Their success to date is very encouraging for future even more ambition applications, like the ILC.

-- Barry Barish