Director's Corner

25 November 2009

What drives the development of technology?

Today's issue features a Director's Corner from Marc Ross, Project Manager for the Global Design Effort.

Five years ago, when superconducting radiofrequency (SCRF) technology was chosen for the International Linear Collider, there were precious few high-gradient, 35-Megavolts-per-metre (MV/m) cavities. Now the picture is quite different: this autumn we congratulate our industrial and institutional partners in Japan and US for successfully fabricating, processing and testing several high-performance nine-cell superconducting cavities. We also congratulate the European XFEL team, working at DESY, for the successful construction, assembly and testing of the first ‘full-ILC-performance’, 32 MV/m average, cryomodule. Taking all ILC cavity tests into account, a globally-based pattern of achievement and success emerges, giving confidence that we will meet or even exceed the forward looking-goal we set for ourselves at Snowmass in 2005. The steps along this path: chemical rinses, diagnostics for inspection, company visits, standardised recipes and inter-institutional database teams reflect the journey and have been described in earlier ‘Director's Corners’, written by me and by Akira Yamamoto.

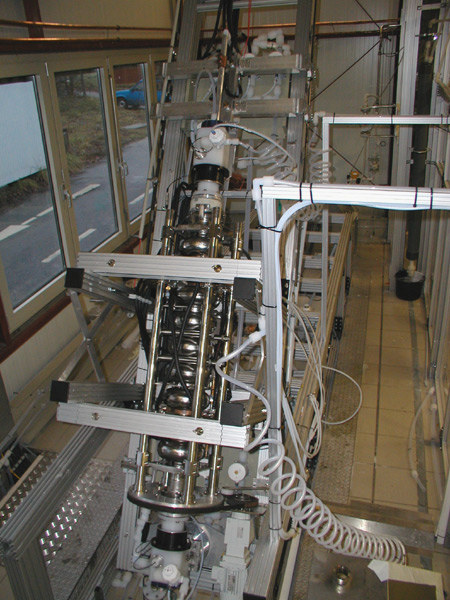

Cavity electro-polishing system installation at DESY... Cavity electro-polishing system installation at DESY... |

...and at KEK. These two systems perform essentially equivalent functions – but the details of how they do it are quite different. ...and at KEK. These two systems perform essentially equivalent functions – but the details of how they do it are quite different. |

Of course, the journey is far from over.

What are the key ingredients to the successful development of technology? Is it just money, as the Beatles song suggests? Access to real resources is quite important, of course, but how much have the two pairs of opposites "competition and teamwork" and "diversity and centralisation" contributed to our progress? Paradoxically, these two pairs are the key to our progress, and, some might claim, to progress in any coordinated, distributed enterprise. Within the Global Design Effort, we promote diversity, yet constrain it through tight interface definition (so-called ‘plug-compatibility’). And we can hardly avoid inter-institutional rivalry, not to mention industrial competition.

To see the process in action, in two different ways, we can have a look at two workshops held this autumn: the biennial SRF Workshop, held this year in Berlin, Germany ('SRF2009'), and the DOE-organised 'Symposium on Accelerators for America's Future'. Presentations from both are online and make fascinating reading. The SRF Workshop is the chief meeting devoted to all aspects of SCRF R&D, as their website proclaims: "the latest advances in the science, technology, and applications of superconducting RF." This year it was a "grand success." The DOE Symposium on the other hand was intended to identify current and future needs of stakeholders, seek out crosscutting challenges-technical, cost, policy-whose solutions may have transformative impacts on opportunities for the future, identify the areas of accelerator R&D that hold greatest promise, and provide guidance to bridge the gap between basic accelerator research and technology deployment, in other words, to figure out how to best to deploy accelerator R&D to meet the needs of the nation (US).

At SRF2009, we talked about the interplay between diverse, somewhat competitive, basic R&D, as one might find in a university setting, and managed R&D in support of a specific project. An example of the latter is the R&D towards the ILC-GDE SCRF goals, 'S0' – study of gradient limitations, 'S1' – construction of an ILC cryomodule and 'S2' – test of several cryomodules with full-intensity beam. It is widely believed that generic R&D on technology is best motivated by high-level, project-related goals. Real technical progress on RF superconductivity in the last two decades, broadly aimed at the linear collider, first TESLA and now ILC, shows the effectiveness of using a strong, yet conceptual 'project' to guide basic R&D. This is an example of how best to bridge the gap between basic accelerator research and technology deployment (the last goal from the DOE Symposium) and it clearly works in both directions – strengthening basic R&D and focusing intrinsic strength on project goals. The symposium goals proclaim correctly that our challenge is to achieve the three-way balance between planned (or conceptual) project needs, institutional (or industrial) infrastructure and expertise, and basic, generic research strategies. The proliferation of accelerators for applied science in the last two decades has led to the application of a more efficient alignment of institutional strengths through the US national laboratory complex. This process is now relatively mature and, at present, each lab's core competencies are readily visible and serve as a tool in developing new projects and collaborations.

The International Linear Collider Global Design Effort provides the needed framework for such inter-institution, inter-regional R&D. We developed detailed performance requirements in support of a specific final-product application, (the ILC), and we benefit from a steady stream of impressive results.

-- Marc Ross