Director's Corner

9 December 2010

Barry Barish |

Evolving the ILC baseline: main linac operating gradient

Last week I described the motivation and the process for evolving the baseline for the technical design effort that we will be carrying out over the next two years, culminating in a Technical Design Report (TDR) at the end of 2012. The baseline for the TDR is being evolved by making a series of specific changes, of which four of the proposed changes have been determined to have impacts that require a “top-level change control” action. I defined that process last week.

Today, I will describe the first of those proposed change actions completed in recent weeks. In short, as a result of a year-long process culminating in an agreed set of conclusions at the Baseline Assessment Workshop in September, the following statement was made: “We propose to keep the specified main linac accelerator operational gradient of 31.5 megavolts per metre (MV/m) with a quality factor (Q0) of 1010, on average, with a gradient spread of less than 20 percent.” I have evaluated this proposal with the considerable help of the Change Evaluation Panel, also described last week, and have approved this request, which defines the spread and safety margins required to run the main linac at the specified gradient.

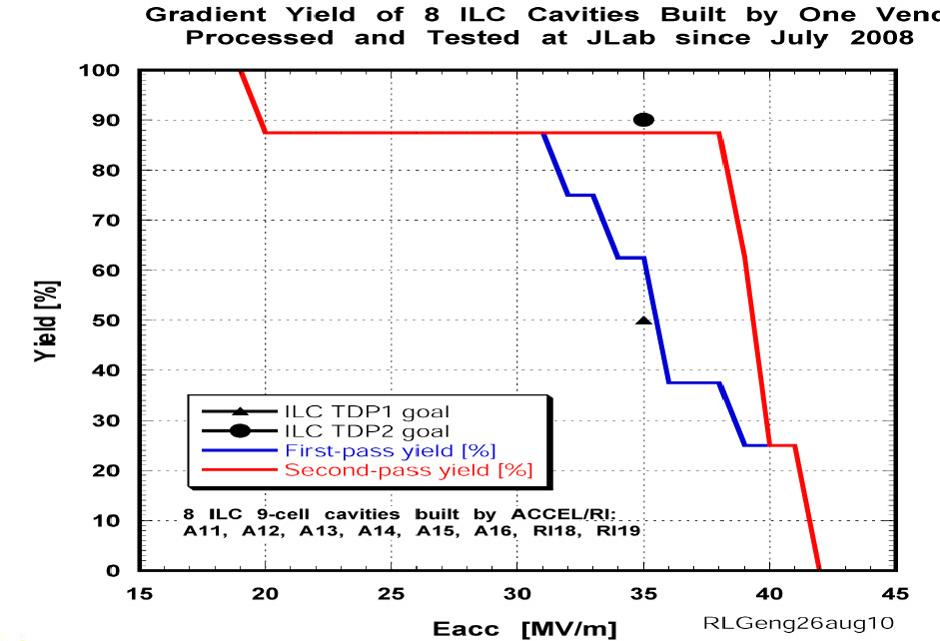

The operational gradient affects the costs, mostly because of its direct relationship to the length of the linacs and the risks (or confidence) in reaching the specified maximum energy of 500 GeV. The choice of operating gradients also defines the goals of the gradient R&D towards the TDR, as well as the production and acceptance requirements for industrialisation, assembly, testing and performance. The current status of the global R&D effort to achieve the long-stated high gradient cavity performance of 35 MV/m, with Q0 ≥ 8 109, is a demonstrated second pass production yield of 56 percent. We reached our 2010 goal, and this gives us confidence that we will be able to achieve our goal of 90 percent yield by the time of the TDR. Of course, we will eventually optimise the production of cavities for cost-to-performance, and that will determine the actual strategy for reprocessing and other tasks. To reach that point, however, we will need more data and we look forward to performance data from the large number of European X-ray Free Electron Laser (XFEL) cavities that will be produced using the ILC process.

Our high-gradient cavity R&D programme will continue during the period to the TDR (and beyond), and we fully expect some advances from that programme, such as improvements in the manufacturing process, especially in quality control, in improvements in the preparation with surface treatment, and in the possibility of incorporating more time-cost effective processes such as vertical electropolishing. We will also undertake further studies towards the understanding and reduction of field emission.

Producing high-gradient cavities is only part of the problem. For the ILC we will install nine such cavities into a single cryomodule and operate it as a unit. The proposal that I have approved sets the average operating gradient of 31.5 MV/m for operation of the main linac cryomodules, with a spread of up to 20 percent. We believe these parameters are realistic and achievable, but represent challenging goals. I should also note that this change action has no significant impact on the physics potential of the ILC and the experimental community has expressed no concern.

The starting point in achieving our cavity goals is producing cavities with gradient in vertical tests of > 35 MV/m, yielding a set of cavities with average gradient of ≥38 MV/m. A loss is expected (or assumed) of roughly three percent in going from vertical tests to installation in horizontal cryomodules. The main linac operational gradient must be set a value where the cavities can operate indefinitely, following installation in the main linac. We estimate that an operational limit of not more than 1.5 MV/m below the limit seen in the cryomodule test should be sufficient, and an operational controls margin gradient of not more than three percent should also be a reasonable expectation. Putting all these factors together, we obtain our best present value of 31.5 MV/m for the proposed operating gradient.

If our R&D programme continues its recent successes, it is possible that we will exceed these goals, but at this point we are setting what we believe are achievable goals for the end of 2012 – further improvements will reduce the machine length and realise some additional cost savings. Approving this proposal for the baseline for the main linac operating gradient for the TDR represents an important step towards developing a realistic design for the ILC. The main linac is the central technical element in the ILC and the successes of our R&D programme has already gone a long way toward putting a high gradient linac on firm footing for the ILC.

-- Barry Barish