Director's Corner

15 January 2009

Barry Barish |

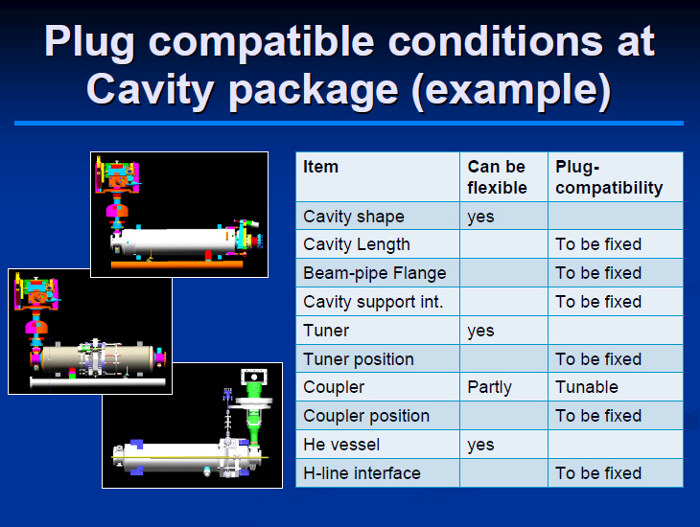

Plug compatibility: rationale and technical aspects addressed

An interesting and challenging concept that has emerged in developing the ILC's technical design is that of plug compatibility for the superconducting radio frequency (SCRF) accelerating systems. Plug compatibility is not a new term invented for ILC – a common definition might be that the term describes manufactured hardware that is designed to be interchangeable with another vendor's product, even though internal details may differ. This concept, as applied to our ILC design, has been introduced, discussed and intensively debated over the past year. A recently released note from our project managers, simply entitled "Plug Compatibility", provides a good summary of the present thinking of our project managers. In this note, they give their rationale and discuss technical and engineering aspects of SCRF plug compatibility from their point of view. It also addresses various concerns that have arisen.

Example of plug compatibility for the cavity package Example of plug compatibility for the cavity package |

Akira Yamamoto, promoter of the SCRF plug compatibility concept Akira Yamamoto, promoter of the SCRF plug compatibility concept |

I first discussed the concept of plug compatibility in a Director's corner more than a year ago, when I discussed whether we require unified designs of subcomponents to be manufactured everywhere in the world, or whether we should develop plug-compatible designs. The plug-compatible approach allows for differences that best suit variations that result from local conditions, innovation and optimisation. The plug-compatible approach has become central to the approach advocated by Akira Yamamoto, SCRF project manager. He gave the motivation and explained his thinking in a follow-on Director's corner. Since that time, there have been extensive discussion and necessary clarifications of the details of the concept as it applies to SCRF components.

Our Accelerator Advisory Panel (AAP), whose job is to give me independent technical assessments of our evolving technical design, raised some concerns. They brought up with me a "number of concerns that could be addressed in a future evaluation of the optimum level of plug-compatibility for globally distributed cost-effective mass-production." The AAP concerns include the question of the practicality of defining "the many interfaces for the successful mixing of components within the cavity package or within the cryomodule." They have also brought up concerns regarding risks of errors from the necessary of monitoring different detailed designs, as well as possible problems in maintenance, approach toward spares, etc.

The Global Design Effort Project Managers have been working hard to define the detailed concept for plug compatibility for the ILC SCRF subsystems, and to respond to the AAP, as well as to other concerns. In their recently issued note, they continue to advocate the plug-compatible approach and they respond to many issues that have been raised. They have especially concentrated on issues that pertain to the ILC R&D Technical Design Phase, which is our ongoing programme to complete an optimised technical design by the end of 2012. An interesting point made in this note is the potential value of a plug-compatible approach for a post-2012 extended R&D phase, a likely possibility as we await approval of collaborating governments. The note points out that plug compatibility will "allow innovating R&D to continue, while still maintaining a rapid transition to a construction phase once approval is maintained." It is easy to imagine that this can be especially important for our programme to develop and implement in the ILC the most up to date high gradient SCRF cavities.

I believe that the discussion and evolving concepts for plug compatibility provide an excellent illustration of the healthy environment we have created to work through difficult issues in a global design process. There are many areas where developing a truly global project forces us to solve problems in new ways. The challenge of developing the plug compatibility concept for the ILC is a good example, as a unified design is the norm for most projects. Adopting a plug compatible approach is a direct result of global optimisation, and finding a robust and workable way requires much thought, dialogue and hard work. The note just released by our project managers is certainly not the end of the story, but it is an important step towards a truly global technical design, and as importantly, it is a validation of the GDE design process.

-- Barry Barish