Director's Corner

17 December 2009

Strawman Baseline 2009 Report preparations and the new ILC Cost Estimating Tool

Today's issue features a Director's Corner from Peter H. Garbincius, Global Design Effort Cost Manager.

Season's Greetings!

We are currently preparing the SB2009 proposal with the goals of reducing the overall cost, optimising the facilities, and improving the performance of the accelerator for the next ILC baseline. The SB2009 proposal will be presented in a report being generated under the leadership of the Global Design Effort (GDE) Project Managers Marc Ross, Akira Yamamoto, and Nick Walker with Nobu Toge as editor (a demanding task–master). SB2009 will be reviewed by the Accelerator Advisory Panel in Oxford in early January. Barry Barish, the ILC GDE Director, will ultimately decide what items contained in the SB2009 proposal will be adopted to modify the Reference Design Report (RDR) into the new baseline for the GDE Technical Design Phase 2 (TDP–2), which will produce a technical design, preliminary construction schedule, and new cost estimate by 2012.

The concept of SB2009 has been evolving from the earlier minimum machine studies documented in November 2008, through the Accelerator Design and Integration (AD&I) meeting at DESY in May and the Albuquerque ALCPG09 meeting in late September and early October. During the first week of December, a meeting was held at DESY to review the status of the SB2009 document, chapter by chapter, including the contributions for the design of each accelerator area system, the radiofrequency (RF) cavity R&D, the new conventional facilities concepts, and the cost impacts of each of the baseline changes under consideration.

Of course, any changes under consideration must not decrease the science capabilities of the RDR design or increase the risk of attaining our goals. Since Albuquerque, the ILC Research Director and leaders of the World Wide Study (WWS) sent a list of questions on the contemplated SB2009 changes. Some of these concerns have been interspersed in the discussion below. Out of the approximately thirty international participants at DESY, seven or eight were representatives of the ILC Detectors and Physics community. Part of the DESY agenda was devoted to a presentation and discussion of these questions and concerns. The GDE responses to these questions have been recently transmitted to the Research Director and leaders of the WWS.

What are some of the actions under consideration for the SB2009 proposal?

Previously, at the March 2008 meeting in Sendai, it was proposed to replace the 6.7–kilometre hexagonal damping rings for the RDR with 6.4–kilometre racetrack damping rings which give smaller bunch lengths to enable the use of single–stage bunch compressors in the ring–to–main–linac (RTML). This reduces the number of cryomodules, the tunnel lengths and the number of full–intensity 5 GeV electron and positron beam stops.

Two new approaches to the distribution of the RF power to the cryomodules, both needing only one tunnel instead of separate beam and support tunnels for the main linac, were described by Barry Barish here. Either of these approaches can save up to 26 kilometres of tunnels!

By reducing the number of electron and positron bunches in half, the low–power approach can save substantial cost for the RF driver systems. However, either a different set of beam–beam interaction parameters would have to be chosen or a novel "travelling focus" employed in order to maintain the RDR luminosity. The detectors and physics representatives asked questions about the beam quality, stability and backgrounds at the interaction point for the low–power approaches.

The low–power (half the number of bunches) approach would allow further reduction to even shorter 3.2 km racetrack damping rings with the same bunch spacing, kicker requirements, and electron cloud mitigation challenges as for the RDR baseline's full number of bunches for the 6.4–kilometre damping rings.

The consolidation and spatial optimisation of the electron source, positron source, beam delivery system, and the injection/extraction lines to/from the damping rings into the central injector complex gives us the opportunity to reduce the total tunnel lengths by an additional 4 kilometres and the other excavated volumes by approximately 2,800 m3 for these four areas.

Many changes are under consideration for the undulator–based positron source. The flux concentrator for initially collecting the positrons in the RDR would be replaced with a conceptually simpler (and less risky) quarter wave transformer (QWT) optics section, although the QWT will require a longer undulator to maintain positron yield and beam intensities. A simpler auxiliary positron source would replace the keep–alive positron source for the RDR, reducing cost and complexity by using the same target, dumps, collection optics, and acceleration components as the full intensity undulator positron source. Moving the positron source to the high–energy end of the electron main linac will increase the positron production yield at higher energy operations, but will provide challenges which may require different operating scenarios to maintain positron yields for electron energies below 150 GeV, the nominal point for positron production in the RDR. In this geometry, the electron beam will not have to be decelerated after the undulator for operations below an electron energy of 150–GeV, simplifying accelerator operations. Finally, placing the positron source at the end of the electron main linac allows the same machine protection elements to be used for both the undulator and the directly downstream beam delivery system, saving tunnel space and technical elements. The positron yield and its effect on overall luminosity over the wide range of operating energies are a concern for the detectors and physics community.

These actions being contemplated have impacts on the costs, machine availability and reliability, and possibly on the overall luminosity, beam parameters, operational stability, and the detectors' environment. As GDE Cost Manager, my role in the SB2009 activities is to compile the cost impacts of all the scenarios under consideration. Today, the evolution of the cost estimate impact consists of 26 individual steps. As the Project Managers and the AAP reviewers ask for more details, I expect this number to grow. We are contemplating these actions not just for the sake of a lower absolute cost estimate at this time. The RDR was a point–in–time snapshot of a not quite complete design which will be brought to a higher level of completion in TDP–2. We realise that TDP–2 may introduce additional cost increases as the designs and costing models evolve. By attempting to reduce costs at this still preliminary stage, we will provide some buffer against such increases in the future.

We acknowledge all the hard work that the accelerator experts, conventional facilities, and technical system personnel have devoted in the preparations for the Albuquerque, DESY, and Oxford meetings, and for the SB2009 report, and thank them for their contributions.

Also during this meeting, many of us visited the DESY Information Technology group where we were shown their new interactive three–dimensional virtual reality display illustrating designs for the ILC tunnel, a laboratory building at Fermilab, and the European X–ray Free–Electron Laser (XFEL), the new accelerator currently being constructed at DESY. The demonstration was very impressive in providing life–size visualisation of structures under consideration, and especially in determining, and thereby avoiding space conflicts at the design phase. It is quite impressive and obviously will be a useful tool for the ILC and other major projects. Thanks to Lars Hagge, Jens Kreutzkamp and Nils Bergel for this demonstration.

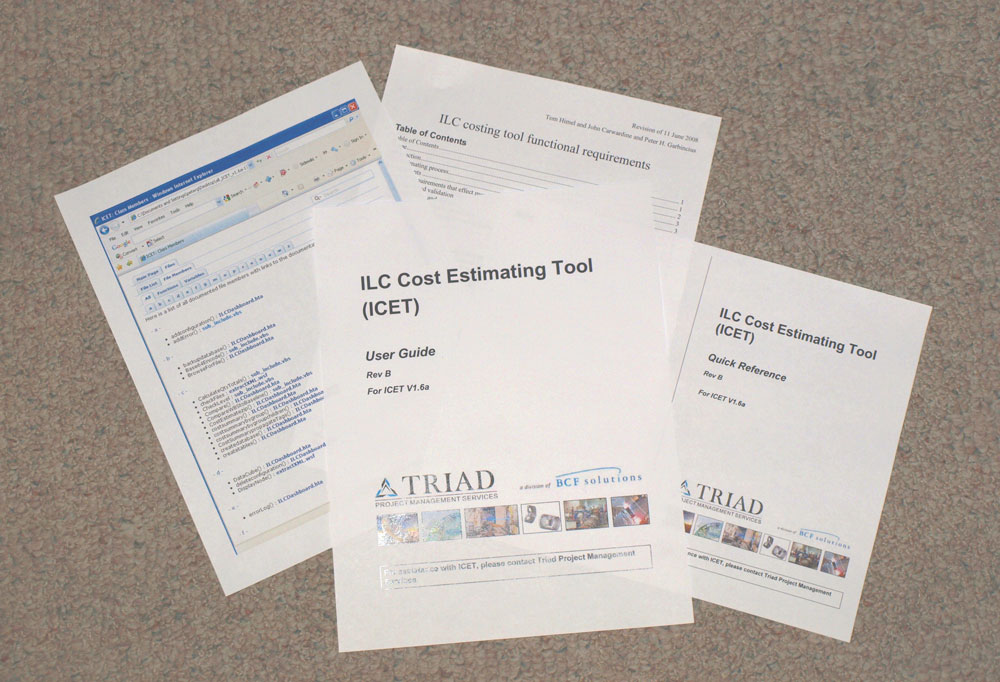

In the middle of November, Triad Project Management Services, completed its 14–month development of the ILC Cost Estimating Tool (ICET – pronounced "Ice–Tea"). Tom Himel, John Carwardine and I first prepared the requirements in summer 2008. The Triad team, Larry Lew, Kevin Long and Spencer Curtis, provided a system of related Excel files, linked through a work breakdown structure (WBS), stored in and retrieved from the ILC Engineering Data Management System (EDMS) with appropriate confidentiality access, and controlled through easy–to–use menus. Visual Basic was chosen for the programming scripts for general clarity and to facilitate the modification of existing scripts and creation of new, custom scripts and reports by ILC–GDE users themselves. In addition to a selection of six pre–formatted Excel reports, the estimating data is stored in a MySQL open source data base. Triad also provided extensive documentation. Besides the usual data fields such as descriptions, quantities, unit costs, and personnel resources, the ICET Cost Estimating Modules (Excel worksheets) also provide for foreign currency exchanges, escalation, risk or cost uncertainties, tags to sort and group cost elements at the WBS, data base, and Excel report stages, and a series of checks on the validity and completeness of the data inputs.

Although ICET has been extensively tested using simulated test data and partial sets of real estimates, the first real task (after SB2009 preparations are completed) will be to install the RDR estimate in ICET. Following that will be the installation of the estimates for the SB2009 studies. We anticipate that the Accelerator Area, Technical, and Global System teams will assist with these installations by providing their new estimate data in the ICET Excel format.

In addition to the people listed above, Tetsuo Shidara, Maura Barone, Kevin Flannery and David Seigle (a summer student who did a tremendous amount of debugging, verification, writing scripts, and formulating reports) of the ILC–GDE, and Lars Hagge, Daniel Szepielak and Jasper Dammann of DESY–EDMS contributed to this Triad–EDMS–ILC activity. Congratulations and many thanks to all!

And finally, Happy Holidays to all!

-- Peter Garbincius