Director's Corner

16 December 2010

Barry Barish |

Evolving the ILC baseline: single main linac tunnel

Two weeks ago I described the motivation and the process for evolving the baseline for the technical design we are undertaking over the next two years. That work will culminate in a Technical Design Report (TDR) at the end of 2012. Last week, I discussed the first of four proposed actions for "top-level change control" and I announced my decision to approve the proposal for the main linac operating gradient. Today, I describe the second of the proposed change actions, which has been stated as follows: “We propose to change the main linac tunnel configuration to one with only a single, accelerator-enclosure tunnel, thereby eliminating the support equipment tunnel proposed in the Reference Design. We propose to develop and include in the baseline two novel High-Level RF power source and distribution schemes ("KCS" and "DRFS") that are better suited to a single-tunnel solution than the scheme proposed in the RDR. A fall-back to the RDR HLRF Technology can be adopted should the R&D on KCS or DRFS not be considered successful.” I have considered and approved this baseline change, following the advice of the Change Evaluation Panel.

At the time of the Reference Design Report (RDR), we chose a two-tunnel configuration for two main reasons: uncertainties about safety requirements, especially with an unknown site location, and the concern about the reliability or availability of the operational ILC accelerator. The safety issues have been researched extensively since that time and we have concluded that it is possible to make a safe single-tunnel configuration that will pass safety standards around the world. We also have studied availability with a simulation program developed by Tom Himel (SLAC) that used data from existing accelerators to establish the parameters and again we have concluded that good availability can be achieved in a single-tunnel configuration.

With the safety and availability issues now in hand, one might conclude that it would be a straightforward decision to change to a single tunnel and thereby significantly reduce the underground tunneling. However, another issue has required much work: how to make the accelerator compact enough to fit well into just one tunnel. That issue has led to two very different schemes that have been proposed for delivering the high-level radiofrequency (RF) to the superconducting cryomodules.

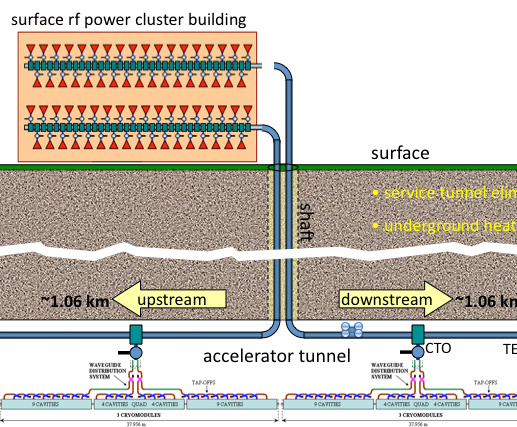

One proposal, the so-called klystron cluster system (KCS), moves the klystrons to the surface, organising them in clusters in large buildings that are separated by approximately one kilometre. Each cluster delivers high-level RF to the underground cryomodules by piping the RF in over-moded waveguides. This solution has the nice feature that it has serviceable klystrons on the surface and out of the tunnel. As a result, the KCS configuration allows for a relatively small-diameter tunnel. The remaining issues with this system include carrying out R&D demonstrations of the system. A potential issue is that failure modes could bring down a substantial piece of the linac, which means that this must be a high-reliability system. The KCS solution is particularly well-suited for deep underground sites or perhaps for shallow underground sites.

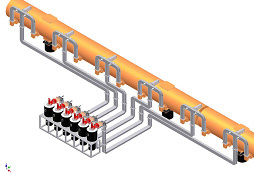

The other system being proposed is a distributed RF system (DRFS) that will consist of about 8,000 compact in-tunnel klystron systems. One unit will have a 800-kilowatt modulating anode klystron that drives two cavities. The DRFS system will also allow a relatively small-diameter tunnel, and, in addition, has the nice feature that it will provide good operational flexibility to take into account performance variability of cavities. On the other hand, cost and maintenance could be important issues and more work will be required in these areas.

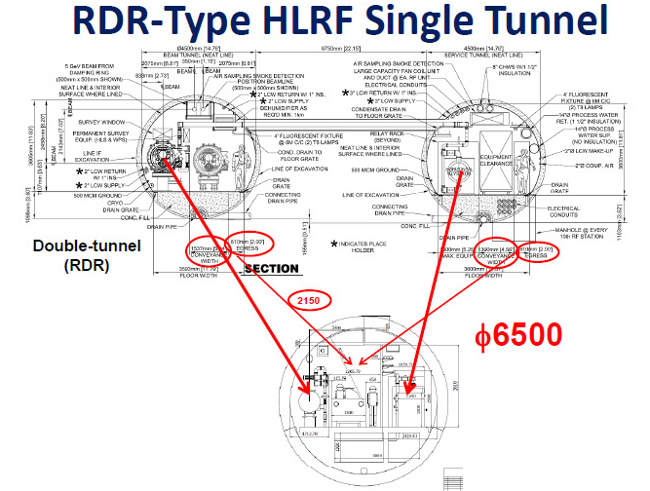

Finally, due to the incomplete R&D on the two new proposed solutions, we also are carrying forward an RDR-like solution, but in a single tunnel. This will require a somewhat larger diameter (~6.2 metres) and a more crowded tunnel. However, this is similar to the European X-ray Free Electron Laser (XFEL) system and represents a reliable fallback should the KCS or DRFS systems become problematic.

The implications of changing to a single-tunnel configuration have been studied in detail over the past year. I applaud the systematic working-through of the large variety of issues so that we now can change to a single tunnel, and have confidence that we have workable solutions for all the types of sites being considered. In order to cover all the possibilities, we will be carrying more than one option for the high-level RF. However, I believe this will enable us to flexibly adapt to whatever site is chosen. During the technical design phase, we will be concentrating on the remaining issues, some of which I mention above, and I am confident that we will end up with a robust single-tunnel ILC design for the TDR.

-- Barry Barish